Maritime

Decarbonizing the shipping industry with onboard methane splitting

Splitting LNG into hydrogen and solid carbon

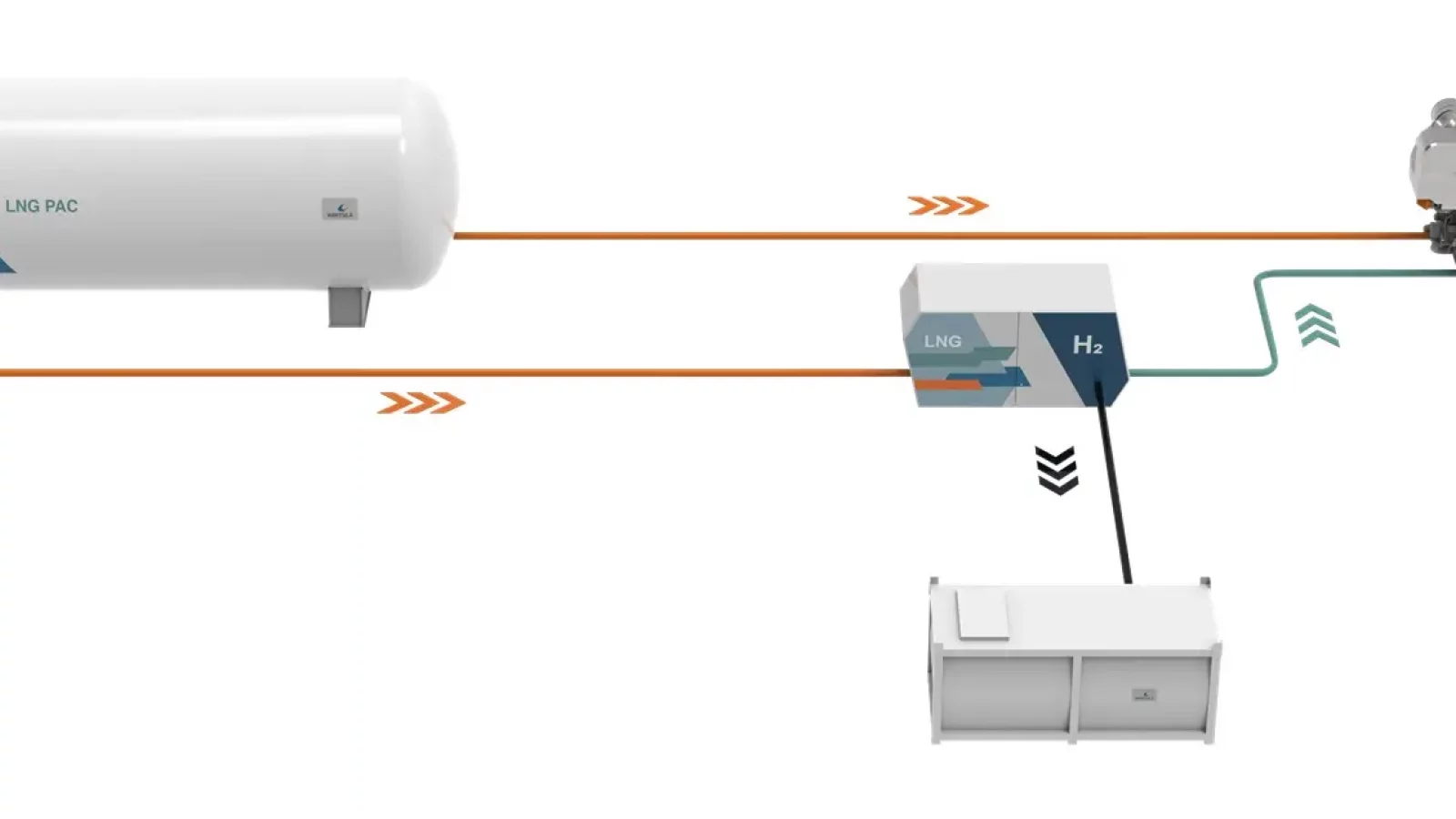

The HYCAMITE™ process splits LNG into hydrogen and solid, high-value carbon. The concept will enable onboard hydrogen production utilizing existing LNG infrastructure.

By producing hydrogen onboard and blending it with LNG, the engines can reduce the vessel’s overall carbon dioxide and methane slip emissions.

80%

FuelEU Maritime regulation has set target to reduce the relative to the average well-to-wake fuel GHG intensity. From a 2% reduction in 2025, accelerating to reach an 80% reduction by 2050.

Use the existing infrastructure

LNG is already available as a bunker fuel for maritime and inland shipping at ports worldwide. By using LNG as a fuel, you can avoid investments in new alternative fuels or infrastructures.

Watch the video below to learn about Hycamite's concept on the onboard methane-splitting process

Reducing carbon dioxide emissions in the maritime industry

Hycamite’s technology can decarbonize LNG, offering the maritime industry an opportunity to reduce carbon dioxide emissions using existing infrastructure.

By 2030, the International Maritime Organization (IMO) aims to decrease the carbon intensity of global shipping by at least 40%, working towards a 70% reduction by 2050 compared to the levels of 2008. Carbon intensity refers to the quantity of carbon dioxide emissions per unit of transportation work, specifically per ton-mile of cargo transported.

Hycamite and Wärtsilä have partnered to develop solutions for maritime decarbonization, focusing on cost-effective hydrogen production from liquid natural gas (LNG) onboard marine vessels.

Additional revenue from high-quality carbon

The concept will utilize the existing LNG infrastructure and enable hydrogen production onboard with Wärtsilä’s LNGPac Fuel Gas Supply System. By producing hydrogen onboard and blending it with LNG, the engines can reduce the vessel’s overall carbon dioxide and methane slip emissions. Hydrogen can also be used in fuel cells onboard.

The HYCAMITE™ process generates solid carbon as a by-product. Instead of producing carbon dioxide as a by-product like traditional methods, solid carbon can be stored and managed more easily onboard.

This technology, applicable to most LNG-fuelled vessels, can support power generation onboard ships with a negative carbon footprint when using bioLNG.

Navigate towards cleaner horizons with Hycamite's maritime decarbonization

Efficiency with LNG solutions

Hycamite’s solution for vessels allows clients to utilize existing LNG infrastructure while reducing emissions associated with LNG use as a fuel. It also helps mitigate methane slip.

However, hydrogen storage presents space challenges on vessels. LNG offers advantages over other low-carbon fuels, as it requires less space compared to hydrogen for a comparable energy content.

LNG is easier to transport than hydrogen because liquid hydrogen must be stored and transported at -253°C, whereas LNG is stored and transported at -160°C. In this case, it is advantageous to utilize existing and proven solutions as much as possible to facilitate rapid industrial scaling and achieve results.

Gaseous hydrogen storage demands a considerable amount of energy and high-pressure compression, reaching up to 350-700 bar. However, utilizing LNG as an energy carrier offers a significant solution to this challenge.

Benefits

Meet the carbon dioxide emission reduction targets

With the HYCAMITE™ solution, you can meet the set decarbonization goals.

Use the existing LNG infrastructure

LNG is already available as a bunker fuel for maritime and inland shipping at ports worldwide. This offers significant savings: By using LNG as fuel, you can avoid investments in other fuel infrastructure.

LNG is easy to transport on a vessel

Compared to other low-carbon fuels, LNG is more easily transportable by vessel and contains more energy per cubic meter than liquid hydrogen. Additionally, storing LNG does not require temperatures as low as storing liquid hydrogen.

A safe way to use hydrogen

Hycamite’s technology can generate hydrogen as needed to be used as fuel. This allows shipping companies to avoid the safety issues linked with storing hydrogen and ammonia. Currently, vessels store substantial amounts of natural gas and other hydrocarbons, so this technology presents a promising alternative.

Collaborative projects

Wärtsilä Veturi

Veturi projects in Finland are large-scale R&D initiatives led by major companies to drive innovation, sustainability, and global competitiveness. They unite businesses, research institutions, and startups to accelerate technology and economic growth. Benefits include investments, job creation, and global market access. Hycamite is part of the Wärtsilä-led Veturi project.

ZEM - Zero Emission Maritime ecosystem

Zero Emission Marine (ZEM) is a ecosystem project led by Wärtsilä, aiming to reduce greenhouse gas emissions in the maritime industry by 60% by 2030 and achieve carbon-neutral or carbon-negative products by 2050.

Flex-CPT II - Flexible Clean Propulsion Technologies

The Flexible Clean Propulsion Technologies (Flex-CPT) project, led by the University of Vaasa, is a consortium aiming to revolutionize maritime and off-road transport by developing flexible, clean propulsion solutions that reduce dependency on single fuel types and significantly lower greenhouse gas emissions.