Low-carbon hydrogen

Affordable decarbonization with Hycamite's hydrogen

Energy efficient low-CO2 hydrogen production

< 1 kg CO2e/kg H2

our carbon footprint in Finland

87% less

energy required compared to electrolysis

Low carbon footprint

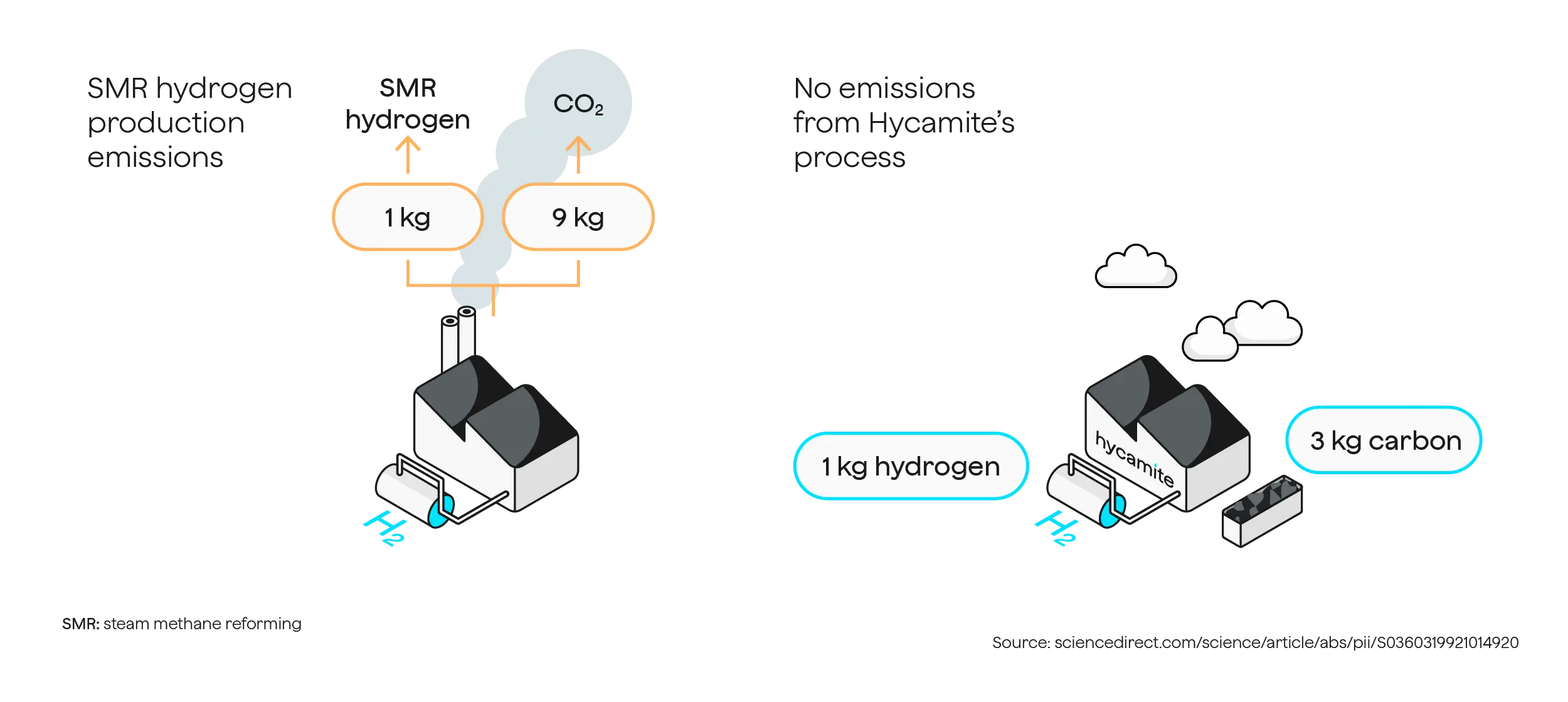

Hycamite efficiently decomposes methane (CH4) into hydrogen and solid carbon using recyclable catalysts, offering a low-emission alternative to steam methane reforming (SMR). Methane can be sourced from various sources, including geologic natural gas, biomethane or synthetic natural gas, even utilizing sidestreams from the petrochemical industry.

The HYCAMITE™ process has an exceptionally low carbon footprint, with hydrogen production emitting less than 1 kg CO2e/kg H2 compared to 9 to 20 kg CO2e/kg H2 from SMR. When using biomethane (Renewable Natural Gas) as a feedstock, the produced carbon acts as a carbon sink, removing carbon dioxide from the atmosphere.

Energy efficient

Hycamite’s methane-splitting technology requires 87% less energy compared to hydrogen production via electrolysis, enabling competitive pricing. We can rapidly and gradually decarbonize the industry by producing decarbonization technology for plants as modules in serial production.

After being piloted in a smaller plant since 2021, our first industrial-scale plant in Kokkola, Finland will soon begin operating. This plant, known as the Customer Sample Facility (CSF), will serve as a technology demonstrator and will focus on producing various high-quality carbon product samples for customers worldwide.

Once fully operational, it will have a capacity of producing 2 000 tons of hydrogen and 6 000 tons of high-quality carbon per year, making it the largest methane-splitting plant in Europe.

[Business model here]

Hycamite efficiently decomposes methane (CH4) into hydrogen and solid carbon using recyclable catalysts, offering a low-emission alternative to steam methane reforming (SMR). Methane can be sourced from various sources, including geologic natural gas, biomethane or synthetic natural gas, even utilizing sidestreams from the petrochemical industry.

The HYCAMITE™ process has an exceptionally low carbon footprint, with hydrogen production emitting less than 1 kg CO2e/kg H2 compared to 9 to 20 kg CO2e/kg H2 from SMR. When using biomethane (Renewable Natural Gas) as a feedstock, the produced carbon acts as a carbon sink, removing carbon dioxide from the atmosphere.

Benefits

Low-cost, low-carbon hydrogen production

Hycamite’s methane-splitting technology requires only 13% of the energy needed to produce hydrogen by electrolysis yet does not release any carbon dioxide emissions into the atmosphere.

Switch to hydrogen one step at a time

Hycamite’s technology enables the gradual introduction of hydrogen into an industrial plant. The user has the flexibility to convert all or just a portion of the plant’s methane into hydrogen. This approach facilitates the immediate reduction of carbon dioxide emissions, even if the current infrastructure is not fully prepared for 100% hydrogen utilization.

Flexible and decentralized hydrogen production

The HYCAMITE™ process can be integrated into existing industrial plants using natural gas as a fuel or raw material. Hycamite plants can be constructed in any size to meet industry’s hydrogen needs.

Quick start with hydrogen

Clients can start using hydrogen immediately. There is no need to wait for other hydrogen production technologies to develop, infrastructure to be built, or renewable electricity to become sufficiently and affordably available.

Scalable technology

Hydrogen production can be scaled up to larger facilities and ramped up quickly to meet clients’ needs for reducing emissions.

No need to transport or store hydrogen

Hycamite’s technology enables on-site hydrogen production for industrial processes, eliminating the challenges associated with hydrogen transportation and large-scale storage.