Potential CO₂ reduction in tire manufacturing: Hycamite’s advanced carbon materials

This article was previously published on LinkedIn by Niina Grönqvist The tire industry is under increasing pressure to minimize its environmental impact and reduce CO₂ emissions. This pressure originates from the significant contribution of manufacturing processes to a tire’s overall carbon footprint. Major tire manufacturers are actively pursuing net-zero strategies to address this challenge. For […]

What has happened in the hydrogen industry and regulation during the last two years, and what will happen next?

This article was previously published on LinkedIn by Matti Malkamäki A little over two years ago, in December 2022, I wrote an article on LinkedIn advocating amendments to the EU’s regulations to make them more technology-neutral and focused on the outcomes regarding carbon recovery. Now, it’s time to evaluate what has happened since then and […]

The exponential energy opportunity: Hycamite’s role in transforming the U.S. economy

This article was previously published on LinkedIn by Carolina M. Ahlstrand In June 2024, Matti Malkamäki and I were part of the largest Finnish delegation to visit the United States, led by H.E. Douglas Hickey, the U.S. Ambassador to Finland. During our discussions with U.S. Secretary of Commerce Gina Raimondo and our meetings with Governors […]

Decarbonized fossil fuels can solve shipping’s emissions problems

This article was previously published on LinkedIn by Tommi Viiperi Rapid action is needed to reduce carbon dioxide (CO₂) emissions from maritime transport. Maritime transport accounts for almost 3% of global CO₂ emissions. Between 2023 and 2050, maritime transport will grow significantly due to expected increases in world trade and population growth. The maritime sector […]

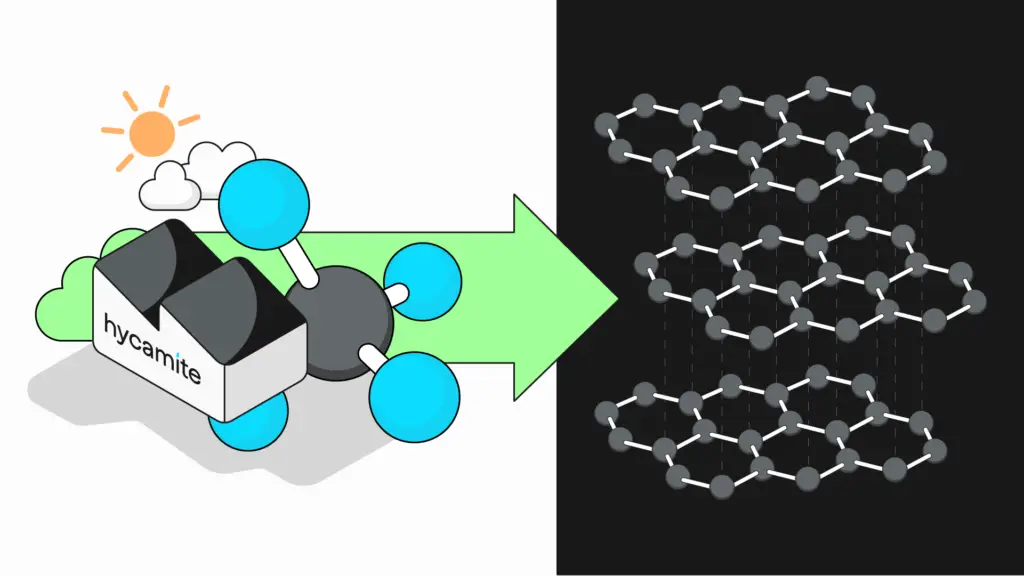

Synthetic graphite with a very low carbon footprint? It’s possible!

We completed a new proof of concept to produce graphite. With it, we can make large amounts of synthetic graphite from methane with a very low carbon footprint. Emissions related to graphite production can be radically reduced.

We can decarbonize car batteries by splitting methane

Electric vehicle batteries, supercapacitors, electric cables and building elements made with composite materials or concrete can be made with significantly lower life cycle emissions. They can even be significant carbon sinks. This is possible with high-quality solid carbon captured using the latest methane-splitting technology.

The largest methane-splitting hydrogen plant in Europe will begin operations this fall

Hycamite is constructing Europe’s largest methane-splitting hydrogen plant in Finland. The next ones will be built in the USA. The modular structure makes it possible to scale up production plants rapidly. With a network of similar plants, we will provide cost-efficient, low-carbon hydrogen and high-quality carbon as a service around the globe.

A hydrogen valley can lift Finland from an investment slump

Finland needs hydrogen valleys that are more than just hubs for the hydrogen industry. They can help us get investment in Finland going.

It doesn’t matter what the color of hydrogen is as long as it lowers net emissions

Deng Xiaoping, the father of modern China, famously said, “It doesn’t matter whether a cat is black or white, as long as it catches mice.” This principle gave rise to unique economic growth in China. The same should apply to hydrogen to boost the global hydrogen economy – color shouldn’t matter. Instead, the focus should be on the carbon intensity (CI) of the hydrogen. This CI should be calculated using a harmonized global methodology allowing for ease in cross-border trade.

Hycamite’s perspective on the proposed 45V regulation for clean hydrogen production

On December 22, 2023, the Internal Revenue Service (IRS) and the U.S. Department of the Treasury (Treasury) released the proposed regulations on how to implement the 45V Clean Hydrogen Production Tax Credit.